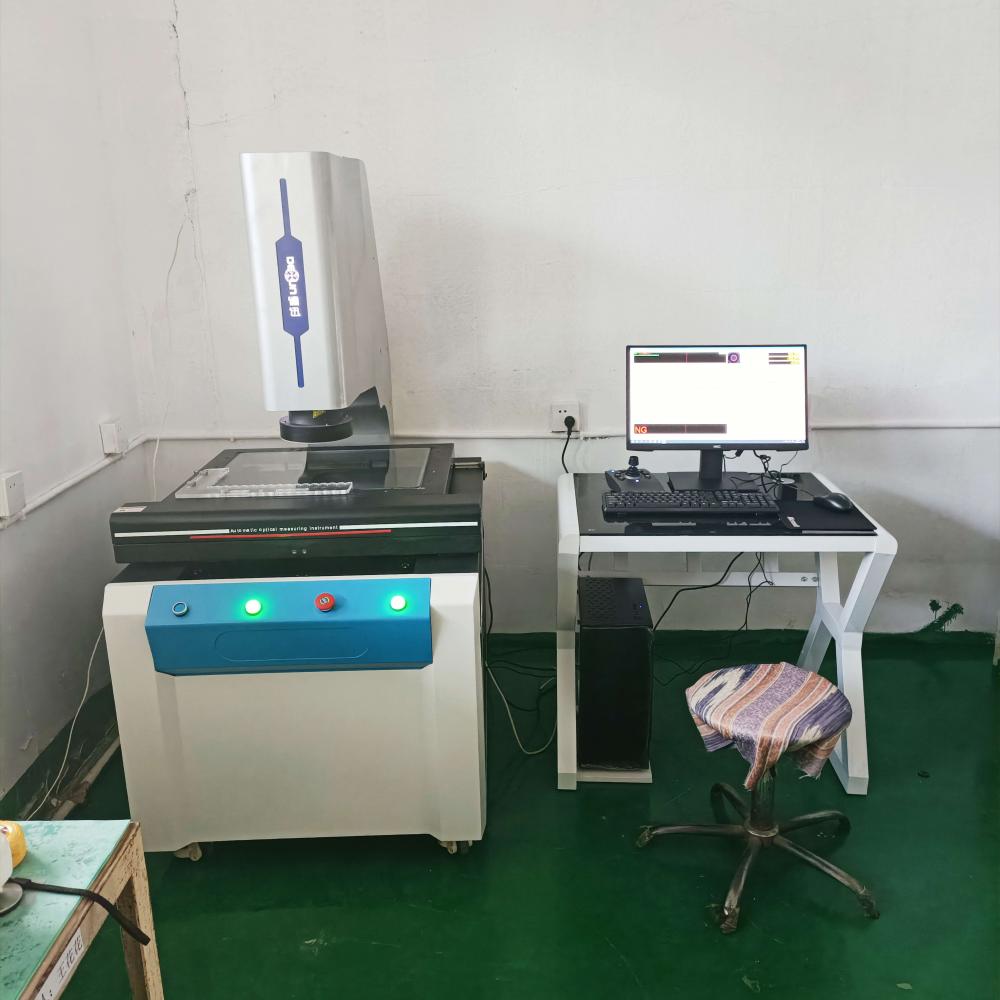

Model No.:VMM5040

Brand:DEXUN

Certification:Scoc, Reach

Support Customization:Obm, Odm

Place Of Origin:China

Measuring Range:500*400*180

Glass Bearing:30kg

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case binding |

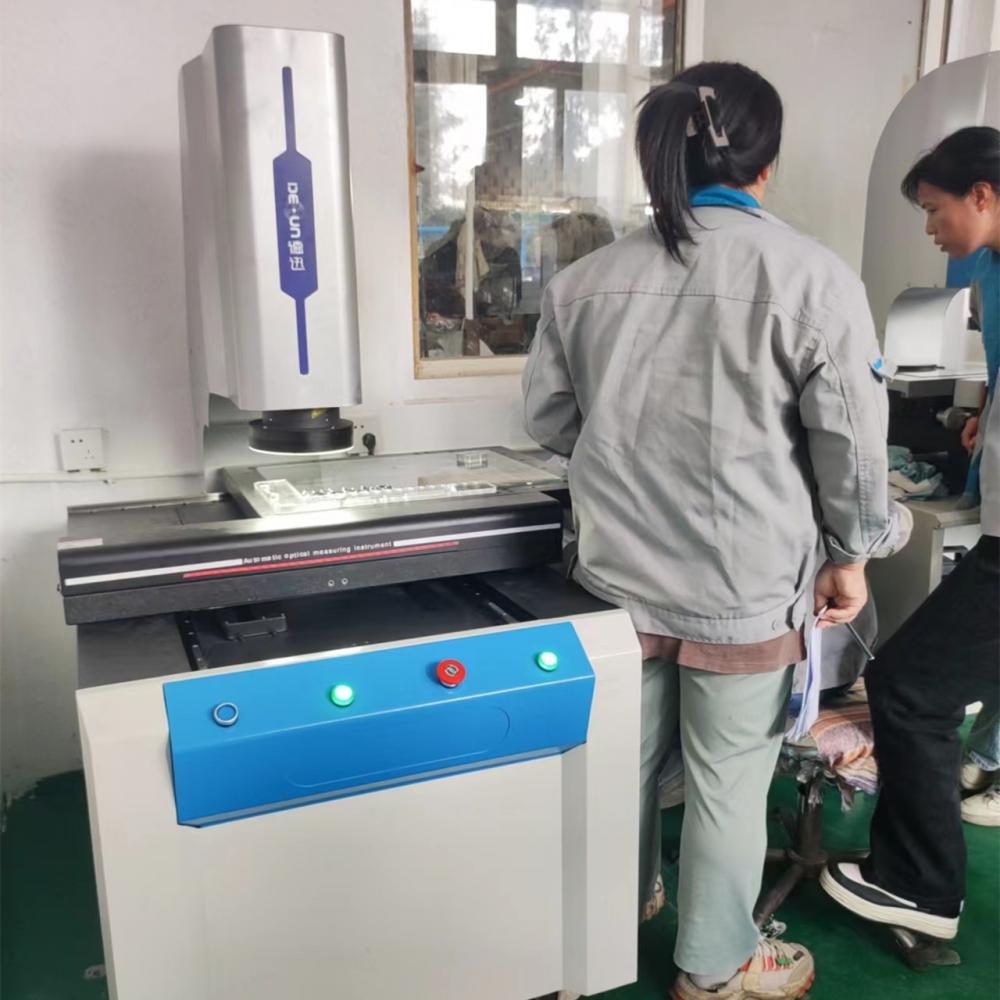

| Picture Example | : |

The full-automatic one button flash spell special Measuring Instrument is a one button fast special measuring equipment designed and manufactured by our company for large-scale two-dimensional workpiece multi size detection. The equipment is characterized by large measuring travel, fast detection efficiency and high detection accuracy. The equipment is equipped with rich image measurement modules to meet the measurement of different workpieces. The equipment is composed of high-precision control system and high-precision image detection module. The motion control system uses imported servo motor with grinding ball screw and high-resolution grating ruler, with high positioning accuracy and low noise. The image detection module uses high-resolution camera, Automatic zoom lens, multi angle annular light source and LED remote core cold light source can realize the detection of two-dimensional plane dimensions such as profile, point, line, circle, arc and distance of different workpieces. The equipment contains expansion modules.

characteristic:

Precise flash measurement and instant response;

Automatic image matching function, measuring workpiece can be placed at will without positioning fixture, focus adjustment and manual loading platform

Operation; The software adopts advanced image edge processing

It can realize the measurement of multiple positions of the measuring workpiece, increase the measurement size, and also does not consume much measurement time;

The least square regression processing can automatically remove burrs and outliers, and minimize the impact on the feature location.

Multiple workpieces can be placed at random, automatic identification can be measured at the same time, without single measurement for each workpiece;

Efficient batch measurement, more than 20000 dimensions can be measured at one time within the measurement range, and the measurement time of 100 dimensions is less than 1

Second, greatly shorten the measurement time and improve the measurement efficiency.

Automatic workpiece identification without positioning

1. The base is made of marble (Grade 00), and the solid platform design ensures high stability and rigidity.

2. It adopts grinding ball screw and precision linear guide rail, which are controlled by integrated controller with high precision, high speed and high stability.

3. The three axes adopt imported Panasonic servo drivers and motors.

4. The 5 million Sony chip large target high-speed optical fiber high frame rate digital camera does not need to carry an image capture card for clearer imaging

5. Low distortion tele lens, higher precision and wider field of vision.

6. Programmable surface light and remote core parallel cold light source, with adjustable brightness.

7. Equipped with 0.5um grating ruler.

8. Combined with powerful automatic splicing measurement software, it can be programmed for automatic measurement.

9. Applicable industries: aviation, aerospace, military industry, automobile, new energy, photovoltaic, food, precision electronics, precision machinery, mold, PCB, LCD, hardware, plastic, medical, education, measurement, scientific research institutes and other industries.

The full-automatic one button flash spell special measuring instrument is a one button fast special measuring equipment designed and manufactured by our company for large-scale two-dimensional workpiece multi size detection. The equipment is characterized by large measuring travel, fast detection efficiency and high detection accuracy. The equipment is equipped with rich image measurement modules to meet the measurement of different workpieces. The equipment is composed of high-precision control system and high-precision image detection module. The motion control system uses imported servo motor with grinding ball screw and high-resolution grating ruler, with high positioning accuracy and low noise. The image detection module uses high-resolution camera, Automatic zoom lens, multi angle annular light source and LED remote core cold light source can realize the detection of two-dimensional plane dimensions such as profile, point, line, circle, arc and distance of different workpieces. The equipment contains expansion modules.

Applicable industries:

Aviation, aerospace, military, automobile, new energy, photovoltaic, food, precision electronics, precision machinery, molds, PCB, LCD, hardware, plastics, medical, education, measurement and research institutes and other industries.