Model No.:DX-3020

Brand:DEXUN

Certification:Reach, Scoc

Support Customization:Obm, Odm

Place Of Origin:China

Size:300*200*180

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case binding |

| Picture Example | : |

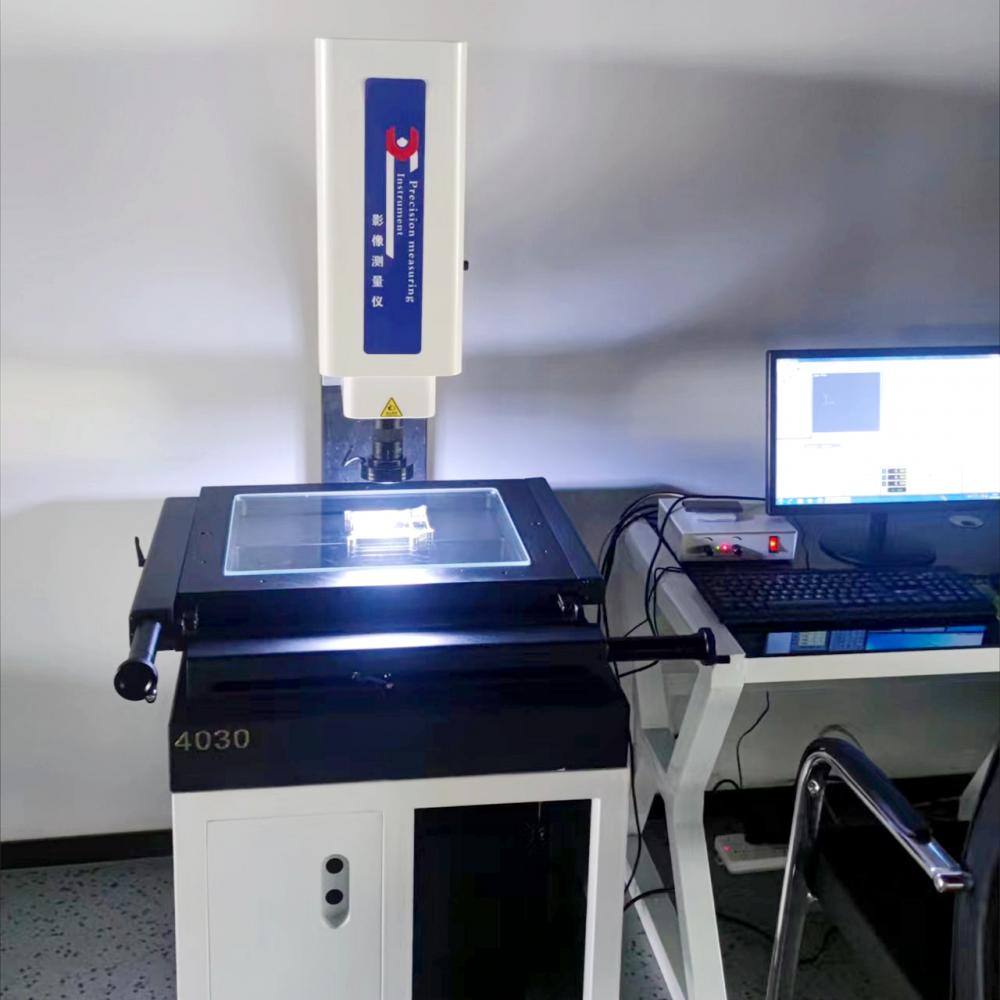

The degree of intelligence of manual image Measuring Instrument is low. Especially in terms of software functions, intelligent image scanning and calculation cannot be realized, but manual extraction depends on manual judgment: each person manually extracts according to their own human eye judgment, which results in large errors due to different measurement results. Therefore, in addition to its own accuracy limit, the errors caused by human operation also lead to the randomness and poor accuracy of the measurement results of the manual image measuring instrument.

The automatic image measuring instrument has made rigorous large data calculation for primitive edge extraction, image scanning, data analysis, etc. through powerful computer algorithms, which can provide users with more automatic and standardized operation steps and methods, avoid manual operation errors of the image measuring instrument, and ensure higher and more consistent measurement accuracy of the automatic image measuring instrument.

2. Higher precision processing efficiency:

Due to the advantages in intelligence, the measuring efficiency of automatic image measuring instrument is 10-50 times that of manual image measuring instrument, and it is higher in PCB, LCD and other industries. When measuring the same workpiece, if the automatic measurement takes 1 unit of time, and the manual measurement takes 10-50 units of time, the manual imager will consume 9-49 times more unit time, which will consume a lot of hidden costs of the enterprise!

3. The manufacturer provides good after-sales service:

As the manual image measuring instrument is a low-end product, manufacturers and dealers mainly rely on volume to survive, and do not have the energy to do after-sales service. Once the equipment fails, it is relatively difficult to repair. The automatic image measuring instrument pays attention to brand building, and has perfect after-sales service to solve various problems in the use process of customers. For the problems reported by customers, they should reply and propose solutions within one working day, assist in remote operation, and provide long-term warranty service

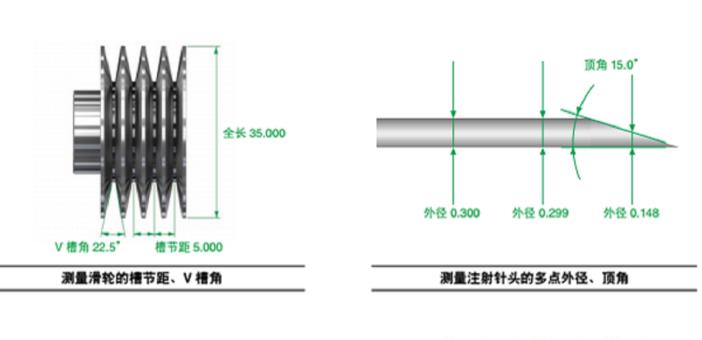

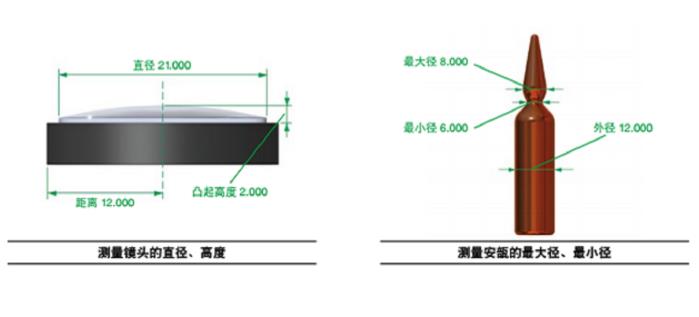

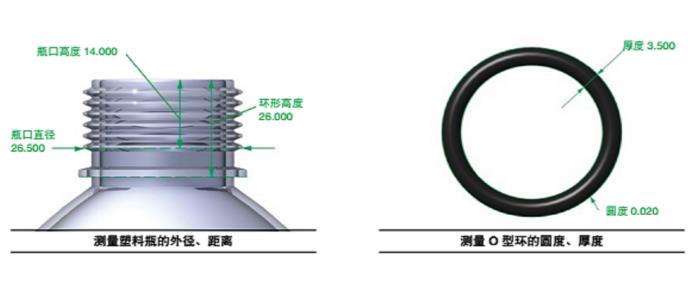

The instrument can efficiently detect the contour and surface shape of various complex workpieces, such as: templates, stampings, cams, spiral spinning, gears, forming milling cutter and other tools, tools and parts, as well as terminals, clocks, diamonds, etc.

More widely used, it is widely used in machinery, mold, instrument, electronics, light industry and other industries, and it is an indispensable measuring verification equipment for measurement rooms and production workshops.

Instrument measurement accuracy: (3+L/200) μ m

X, Y coordinate resolution: 1 μ m

Data processing system: multi-function data processing system, full Chinese display can do multi-point sampling, coordinate rotation, point, line, distance, angle detection RS-232 data output, can be directly imported into CAD.